Yugong Double Layer Ring Die Rice Husk Ash Pellet Making Machine

Basic Info

Model No.: LGX-900

Product Description

1.kinds of agri waste can be the materials

2.Auto lubrication system

3.Dia 4-12mm pellet

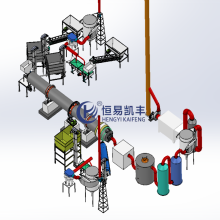

Yugong Double Layer Ring Die Rice Husk Ash Pellet Making Machine Rice Husk Ash Pellet Making Machine is applied to the material with low adhesiveness and low shaping ,such as the rice husk, sunflower seed husk, peanut shell and Other fruit shell branch, trunk, bark and other wood waste; a variety of crop straws, rubber, cement ,ash and other chemical materials. The Pellet Mill is widely used in the feed plant, wood processing, fuel plant, fertilizer plant and chemical plant etc. It is the ideal pressing shaping equipment with low investment and high profit.

Three major differences 1. Die upward, special design, feeding vertically, conducive to cooling.

Three major differences 1. Die upward, special design, feeding vertically, conducive to cooling. Die upward, feed raw material vertically and directly into the pelletizing room where is the right place, no need any other feeding assistant device. If feeding mouth of ring die pellet mill is placed in side face, it will be very difficult for the light weight material goes into the palletizing room, and bring result of uneven feeding even using feeding assistant device. And what’s worse is not conducive to pelletizing room cooling which will shorten the lifetime of transmission system (gear, bearing). 2.Mould static, rollers rotating, raw material is distributed centrifugally and evenly around.

Using a unique double-layer high mould which has a rebounding –effect, raw material will be naturally and evenly distributed in the ring moulds’ inner surface. While normally ring die pellet mill’s rollers are static, die is rotating, no centrifugal force, the material unevenly distributed. Though flat die pellet mill with rotating roller can generate centrifugal force, but the die hole is placed vertically which is inconsistent with centrifugal force direction. 3. Double-layer die, multi-function, high efficiency.

The mould has upper and lower parts, customers could choose two different kinds of specifications of aperture to produce two different size of pellets. When palletize high adhesion raw materials, customer could use higher rollers to press the two-layer holes at the same time to reach four-fold capacity. No any other flat-die or ring-die pellet mill can reach this capacity.

Specifications

Specifications LGX-900 | LGX-550 | ||

| Power (kw) | Host Machine | 90 | 55 |

Pellet Pusher | 1.5 | Spindle drive | |

Electric Grease Pump | 0.37 | 0.37 | |

| Host Machine External Dimension (mm) | 2300*1250*2650 | 2160*1000*1900 | |

Machine Weight ( t ) | 6.8 | 2.6 | |

Rotation Speed (r/min) | 1450 | 1450 | |

Voltage (v) | 380,3phase or customized | 380,3phase or customized | |

Mould Diameter (mm) | 550 | 450 | |

Pellet Size (mm) | 4-12 | 4-12 | |

Palletizing Temperature (°C) | 80-100 | 80-100 | |

| Raw Material Moisture Content (%) | 15-25 | 15-25 | |

Capacity (t/h) | 1.2-1.8 | 0.8-1 | |

Our biomass pellet making machines have been exported to many countries,and to be welcomed. Contact us if you need more details on Rice Husk Ash Pellet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about wood pellet machine、Biomass Pellet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our biomass pellet making machines have been exported to many countries,and to be welcomed. Contact us if you need more details on Rice Husk Ash Pellet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about wood pellet machine、Biomass Pellet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Biomass Pellet Machine

Premium Related Products