Complete Working Line of Charcoal Briquette/Ball Making Machine for Sale

Basic Info

Model No.: Charcoal Ball Line

Product Description

Model NO.: Charcoal Ball Line Product Shape: Ball or Briquette Condition: New Output: 1-3t/H Weight of Briquette Machine: 1300 Specification: CE SGS BV Pressing Mode: Extrude Motor Type: AC Motor Diameter of Roller Sheet: 290 Motor Power: 5.5kw Trademark: leabon Origin: Henan, China Introduction of small briquette machine

High efficient small briquette machine is an equipment which can press variety of coal powder, coal dust, coal slime, coking coal,coke powder, aluminium powder, iron powder, iron scurff, iron oxide skin, actived carbon, slag, gypsum, limestone, plastic, kaolin and tailings into ball.

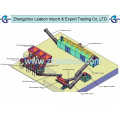

1.Quantitive feed hopper 2.Adhesive feeder 3.Grinding wheel 4.Flat conveyor 5.Belt conveyor 6.Quantitive feeder 7.Belt conveyor 8.back conveyor 9.Ball press machine 10.Belt conveyor 11.Mesh belt conveyor 12.Belt conveyor

Working Principles:

1.This serial ball press used main motor to transmit the motive powder to speed reducer through the V- shape triangle belt and to main drive spindle through coupling, and then uses the main driven split gear to send it to the main driven spindle to make the two rollers fall into step(inverted running with uniform speed)

2.The passive roller is held by the piston of the hydraulic oil cylinder, the hydraulic systen completes the circuit and control valve in the hydraulic systen keeps the system pressure.

3.mateiral are entered evenly into the bunker of the forming machine through the rationling equipment and then poured into the breaker rolls evenly adjusted by the regulating sluice.

4.the breaker rolls of reverted running with uniform speed push a pressure force, from small tp big, on the material

5.the forming pressure maximized at the central sideline and diminished quickly after the material pass through the line

6.then material successfully complete the ball doffing

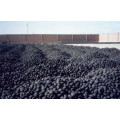

The final prodcution gives is smokeless, non-toxic, nopeculiar smell and environment protective, applicable to the outdoor or indoor barbecue with ventilation, as the heat very large, production time is twice more thatn traditional.

Requirements of raw material for ball press machine:

1.size of material:less than1mm, should be controlled between 30%-40%;

between1-2mm, should be 30-40%

the max size should be no bigger than 3mm, with 20%

2.moisture of material:should be in8%-12%

3.Not aloowed:slad ot Other massive sundries with high hardnedd, or the roll and spindle will be demaged

4.agglomerant or other additives:should be prepared by users in accordance with coal type and the operating environment.

If you want to know more about the machine, please feel free to contact me.

Contact us if you need more details on Kaolin Ball Making. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Charcoal Ball Making、Coal Briquette Making. If these products fail to match your need, please contact us and we would like to provide relevant information.

High efficient small briquette machine is an equipment which can press variety of coal powder, coal dust, coal slime, coking coal,coke powder, aluminium powder, iron powder, iron scurff, iron oxide skin, actived carbon, slag, gypsum, limestone, plastic, kaolin and tailings into ball.

1.Quantitive feed hopper 2.Adhesive feeder 3.Grinding wheel 4.Flat conveyor 5.Belt conveyor 6.Quantitive feeder 7.Belt conveyor 8.back conveyor 9.Ball press machine 10.Belt conveyor 11.Mesh belt conveyor 12.Belt conveyor

Working Principles:

1.This serial ball press used main motor to transmit the motive powder to speed reducer through the V- shape triangle belt and to main drive spindle through coupling, and then uses the main driven split gear to send it to the main driven spindle to make the two rollers fall into step(inverted running with uniform speed)

2.The passive roller is held by the piston of the hydraulic oil cylinder, the hydraulic systen completes the circuit and control valve in the hydraulic systen keeps the system pressure.

3.mateiral are entered evenly into the bunker of the forming machine through the rationling equipment and then poured into the breaker rolls evenly adjusted by the regulating sluice.

4.the breaker rolls of reverted running with uniform speed push a pressure force, from small tp big, on the material

5.the forming pressure maximized at the central sideline and diminished quickly after the material pass through the line

6.then material successfully complete the ball doffing

The final prodcution gives is smokeless, non-toxic, nopeculiar smell and environment protective, applicable to the outdoor or indoor barbecue with ventilation, as the heat very large, production time is twice more thatn traditional.

Requirements of raw material for ball press machine:

1.size of material:less than1mm, should be controlled between 30%-40%;

between1-2mm, should be 30-40%

the max size should be no bigger than 3mm, with 20%

2.moisture of material:should be in8%-12%

3.Not aloowed:slad ot Other massive sundries with high hardnedd, or the roll and spindle will be demaged

4.agglomerant or other additives:should be prepared by users in accordance with coal type and the operating environment.

If you want to know more about the machine, please feel free to contact me.

Contact us if you need more details on Kaolin Ball Making. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Charcoal Ball Making、Coal Briquette Making. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Briquette Machinery > Charcoal/Coal briquette press

Other Products

Hot Products

Cheap Price Wood/Feed Pellets Cooling MachineCE Certificated 1000-2000kgs/H Complete Wood Pellet Plant/Biomass Pellet Production LineHome Use Small Wood Pellet MillChina Supplier Wood Pellet Machine for SaleFeed Extruder/Aquatic Fish Feed Extruder (PHJ)2000kg/H Complete Wood Pellet Production LineKaf 200 Wood Pellet Machine, Wood Pellet MillFactory Manufacturer Ring Die Wood Pellet MachineBiomass Pellet Burner with Reliable Heating CapacityCE approved Yugong wood chips rotary dryer with durable performanceCE certified sawdust dryer equipment&wood/sawdust dryer machineryYugong automatic & hydraulic press concrete brick making machineZhengzhou Flat Die Capacity 0.8 - 1.0 t/h Biomass Sawdust Briquette MachineYugong Ring Die MouldYugong YGM Series Disc Wood Chipper Made in ChinaYugong wood crusher,machine for producing sawdust