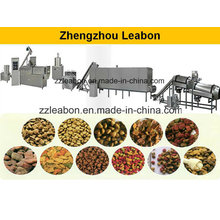

Zhengzhou Leabon Hot Selling Floating Fish Feed Pellet Extruder

Basic Info

Model No.: DGP-60, 70

Product Description

Model NO.: DGP-60, 70 Processing Object: Animal-Derived Feed Screen Mesh: Without Screen Mesh Pellet Mill Type: Pressing Granulator Expanding Method: Dry Expansion Applicable Materials Shape: Powder Feeding Power: 0.4kw Capacity: 120-250kgs/H Certificate: CE SGS BV Final Products Shape: Kinds of Shaps Just Vhange The Model Warranty: 1 Year Without The Spare Parts Specification: CE SGS BV Type: Pellet Mill Processing Technics: Pelletizing Grinding Equipment Type: Roll Crusher Bulking Machine Type: Sigle Screw Bulking Machine Condition: New Main Power: 15kw, 18.5kw Floating Fish Pellet Extruder Cutting Power: 0.4kw Motor: 380V,50Hz,3 Phases Application: Kinds of Fish, Pet Dogs and Cats Certifaciton: CE for Our Production Trademark: LEABON Origin: Zhengzhou, Henan I. Introduction for Floating fish feed pellet machine

It is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog, . Cat etc. The puffing Fish Feed pellets can float on the water surface for over12 hours without water pollution. According to your requirement and production scale, floating fish feed machine can be classified into dry type machine and wet type machine.

II. Working principle for Floating Fish Feed Pellet Machine:

After the material is sent into feeding device, they will be extruded and expanded by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized. Then the expanded material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters. After that a cutting device will cut the formed pellets into different length as required.

III. Features for Floating Fish Feed Pellet Machine:

1. According to different requirements, variety shapes of high-grade feed pellets for fish, shrimps. Etc

2. The finished pellets can keep floating for 12 hours without pollution to water.

3. The floating time can be controlled by the puffing degree adjustment

4. Floating fish feed machine can make pellet from diameter 1mm-12mm just by changing the mould.

5. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and

Also makes the pellets easily to digest.

7. The cutting device can be adjusted to make pellets of different length.

8. The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

IV. Complete flow chart for Floating Fish Feed Pellet Machine:

Raw material preprocessing--crushing--mixing--extruder--cooler--Dryer--flavoring

V. Technology parameter:

Contact us if you need more details on Floating Fish Feed Pellet Extruder. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Fish Feed Pellet Machine、Fish Feed Pellet Press. If these products fail to match your need, please contact us and we would like to provide relevant information.

It is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog, . Cat etc. The puffing Fish Feed pellets can float on the water surface for over12 hours without water pollution. According to your requirement and production scale, floating fish feed machine can be classified into dry type machine and wet type machine.

II. Working principle for Floating Fish Feed Pellet Machine:

After the material is sent into feeding device, they will be extruded and expanded by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized. Then the expanded material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters. After that a cutting device will cut the formed pellets into different length as required.

III. Features for Floating Fish Feed Pellet Machine:

1. According to different requirements, variety shapes of high-grade feed pellets for fish, shrimps. Etc

2. The finished pellets can keep floating for 12 hours without pollution to water.

3. The floating time can be controlled by the puffing degree adjustment

4. Floating fish feed machine can make pellet from diameter 1mm-12mm just by changing the mould.

5. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and

Also makes the pellets easily to digest.

7. The cutting device can be adjusted to make pellets of different length.

8. The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

IV. Complete flow chart for Floating Fish Feed Pellet Machine:

Raw material preprocessing--crushing--mixing--extruder--cooler--Dryer--flavoring

V. Technology parameter:

| Model | Main power (kw) | Feeding power (kw) | Cutting power (kw) | Capacity (kg/h) | Weight (kg) | Screw diameter (mm) | Dimension (m) |

| DGP -60 | 15 | 0.4 | 0.4 | 120-150 | 550 | 60 | 1.5*1.3*1.25 |

| DGP -70 | 18.5 | 0.4 | 0.4 | 180-250 | 600 | 70 | 1.7*1.37*1.25 |

Contact us if you need more details on Floating Fish Feed Pellet Extruder. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Fish Feed Pellet Machine、Fish Feed Pellet Press. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Feed Pellet Machinery > Floating fish feed pellet machine

Premium Related Products

Other Products

Hot Products

Cheap Price Wood/Feed Pellets Cooling MachineCE Certificated 1000-2000kgs/H Complete Wood Pellet Plant/Biomass Pellet Production LineHome Use Small Wood Pellet MillChina Supplier Wood Pellet Machine for SaleFeed Extruder/Aquatic Fish Feed Extruder (PHJ)2000kg/H Complete Wood Pellet Production LineKaf 200 Wood Pellet Machine, Wood Pellet MillFactory Manufacturer Ring Die Wood Pellet MachineBiomass Pellet Burner with Reliable Heating CapacityCE approved Yugong wood chips rotary dryer with durable performanceCE certified sawdust dryer equipment&wood/sawdust dryer machineryYugong automatic & hydraulic press concrete brick making machineZhengzhou Flat Die Capacity 0.8 - 1.0 t/h Biomass Sawdust Briquette MachineYugong Ring Die MouldYugong YGM Series Disc Wood Chipper Made in ChinaYugong wood crusher,machine for producing sawdust